Disc Packaging Testing

Article | May 8, 2018

In total performance, nothing surpasses k8ÓéÀÖâ„¢ °Õ²â±¹±ð°ì® in protecting recordable discs—not even jewel cases. Testing designed to simulate shipping, handling and storage conditions proves it. See charts below.

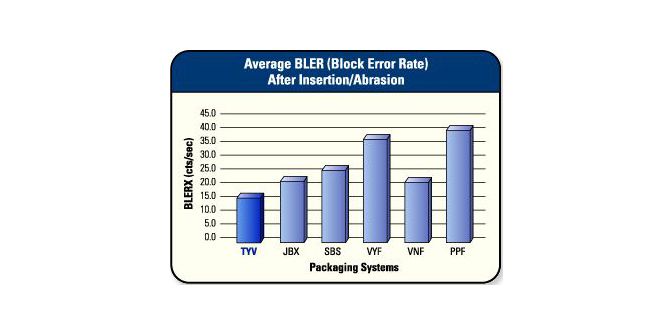

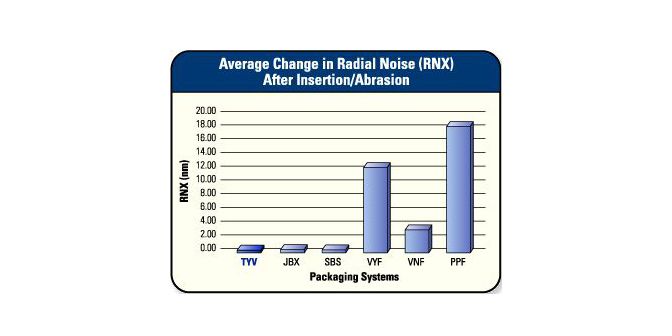

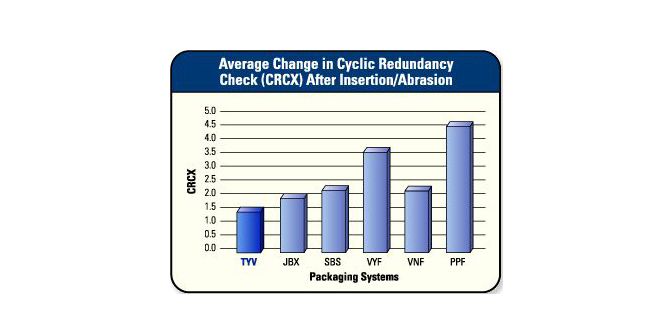

Insertion/abrasion tests, simulating normal use, handling and abuse of discs, showed that °Õ²â±¹±ð°ì® was the only material that did not create additional BLER (block error rate) in the disc. k8ÓéÀÖâ„¢ °Õ²â±¹±ð°ì® also consistently outperformed polypropylene and lined and unlined vinyl film sleeves in guarding against RN (radial noise) and CRC (cyclic redundancy check).

Vibration and drop tests also showed that °Õ²â±¹±ð°ì® protected the discs against damage, but materials like paperboard scratched the disc surface, sometimes causing an unreadable disc.

Elevated temperature tests simulated hot storage conditions. These tests caused some of the other packaging materials to off-gas ammonia, which can result in severe damage to discs, making them unreadable.